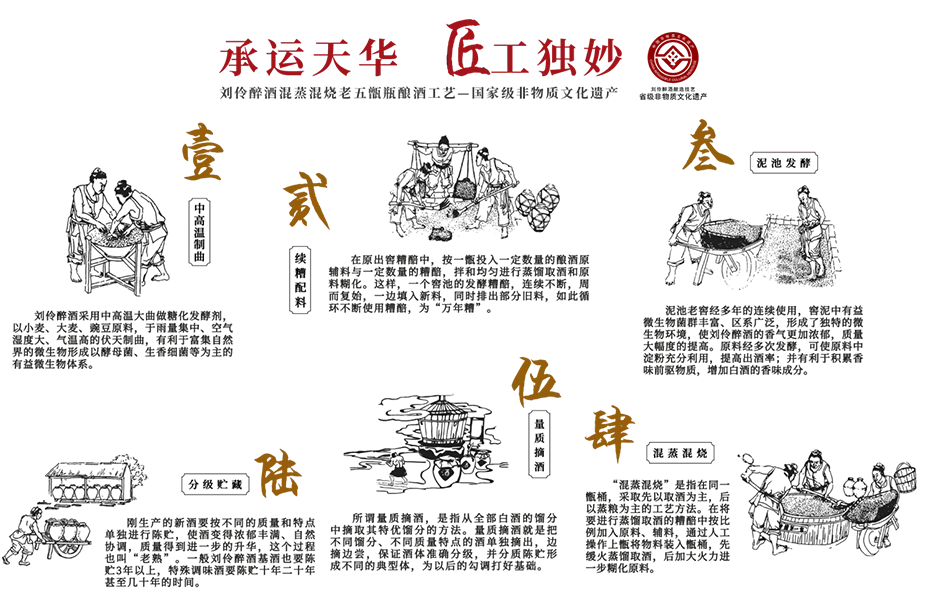

The old five retort process is an important process in the production of traditional Chinese liquor, which is mainly used in the production of Luzhou-flavor liquor. The core of this process is to divide the fermented grains into five times for steaming and blending. Specifically, the operational process of the old five retort process includes the following main steps:

|

1. Raw material requirements: The main raw material is sorghum, and there are wineries that use a variety of grains. Sorghum requires full grain, mature and high starch content. In addition, it is also necessary to use high-temperature koji and fresh dried rice husk. 2. Raw material handlingSorghum needs to be crushed, Daqu needs to be roughly crushed by a hammer mill and then ground into koji powder, and rice husk needs to be steamed and dried for later use. 3. Out of the cellar: In the production of Luzhou-flavor wine, each cellar generally has six steamers of material, divided into back bad and grain bad. When the pit is out of the pit, the pit skin mud is removed first, and then the pit and grain are out of the pit. 4. Ingredients: The ratio of grain to mash and grain to chaff is mainly controlled when batching, and the ratio of grain to koji is controlled after steaming. After adding sorghum powder and auxiliary materials to grain grains, steamed grain and steamed wine, and then added koji powder to continue fermentation. If you return to bad, you will not add new materials, and you will lose them after steaming. 5. Distillation and fermentation: After the processed raw materials are mixed and steamed, the rest is put back into the cellar for fermentation except for the top-level residue. The fermented grains in the wine cellar are stacked in four layers, which are called large slag, second slag, small slag and back to bad. |

The operation points of the old five steamer process include mixed steaming and burning, continuous slag ingredients, steamed auxiliary materials, out of the pool layering, into the pool slag, etc., these steps help to improve the utilization rate of starch and high-quality product rate, to produce a specific style of high-quality wine.